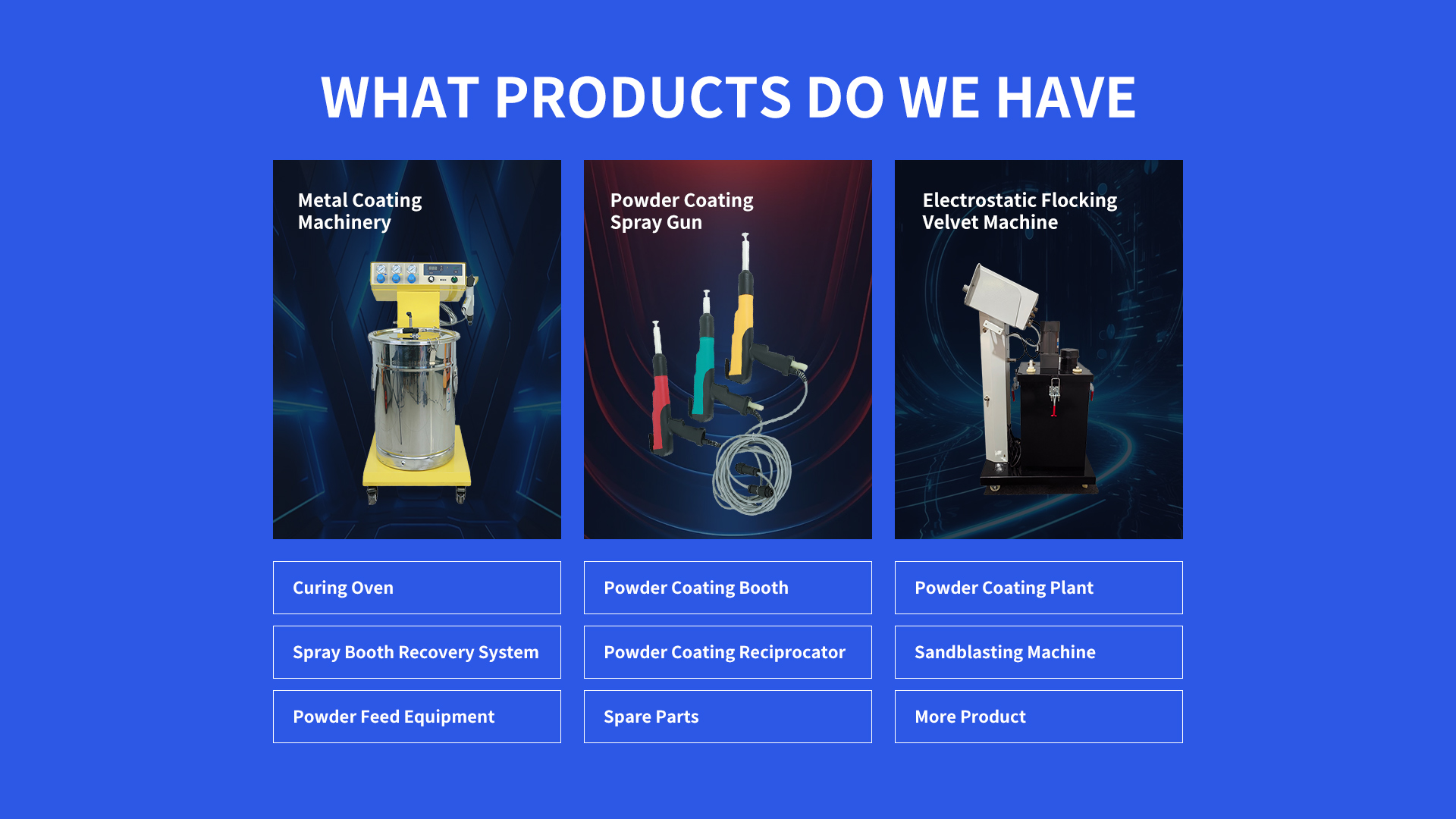

1. Industrial Powder Coating Machine Overview and Key Components

An Industrial Powder Coating Machine consists of a spray booth, electrostatic gun, curing oven, and conveyor system. Pretreatment units clean surfaces via chemical baths or abrasive blasting. Electrostatic guns charge powder particles, ensuring adhesion to grounded metal substrates. Curing ovens fuse the powder at 150–220°C, forming a durable finish. Manual, semi-automatic, and fully automated machines cater to diverse production scales, with robotic arms enhancing precision in high-volume settings.

2. Industrial Powder Coating Machine Applications

These machines coat automotive parts (brake calipers, chassis), aerospace components, furniture, and household appliances (ovens, washing machines). They are also used for architectural metalwork, agricultural equipment, and electrical enclosures. The process delivers corrosion resistance, UV protection, and aesthetic finishes, meeting demands across heavy-duty and consumer-facing industries.

3. Industrial Powder Coating Machine Pricing Factors

Prices range from 10,000forbasicmanualsystemsto500,000+ for automated lines. Costs depend on automation level, oven capacity, and powder recovery efficiency. Energy-efficient ovens or advanced electrostatic guns increase upfront investment but reduce operational costs by 20–40% through lower waste and energy use.

4. Operating an Industrial Powder Coating Machine

Calibrate spray guns for consistent powder flow and voltage (typically 50–100 kV). Maintain curing oven temperatures within the powder manufacturer’s specified range. Ensure proper grounding to prevent electrostatic issues. Clean spray nozzles and filters regularly to avoid clogs and contamination. Automated systems require programming robotic paths for complex geometries.

5. How to Choose an Industrial Powder Coating Machine

Evaluate production volume, material types (steel, aluminum, alloys), and facility space. High-output factories need automated conveyors and multi-axis robots. Small businesses may prioritize compact, manual machines. Verify compliance with ISO safety standards and select suppliers offering warranties, training, and technical support.

6. Industrial Powder Coating Machine Safety Protocols

Operators must wear NIOSH-approved respirators, gloves, and protective clothing. Install ventilation systems to minimize airborne powder exposure. Use explosion-proof lighting in spray booths. Regularly inspect electrical systems and grounding mechanisms to mitigate fire risks. Train staff on emergency shutdown procedures for equipment malfunctions.

7. Design Efficiency of Industrial Powder Coating Machines

Modern designs integrate energy recovery systems in ovens, cutting power use by 25–30%. Closed-loop powder reclaim systems recycle up to 95% of overspray, reducing material costs. Modular setups allow scalability, while IoT-enabled sensors optimize performance through real-time monitoring of temperature and coating thickness.

8. Industrial Powder Coating Machine FAQs

Q: What materials work best with Industrial Powder Coating Machines?

A: Metals like steel, aluminum, and pre-treated alloys are ideal due to their conductivity and adhesion properties.

Q: How often should powder coating equipment be maintained?

A: Clean spray guns daily and replace filters monthly; conduct full system inspections quarterly.

Q: Are industrial powder coatings eco-friendly?

A: Yes, they emit zero VOCs, and unused powder is recyclable, supporting sustainability goals.

Q: What improves coating uniformity in industrial machines?

A: Consistent spray distance, optimized voltage, and robotic precision in automated systems.

Q: Can these machines coat irregularly shaped objects?

A: Yes, adjustable robotic arms or manual spray techniques ensure coverage on complex geometries.

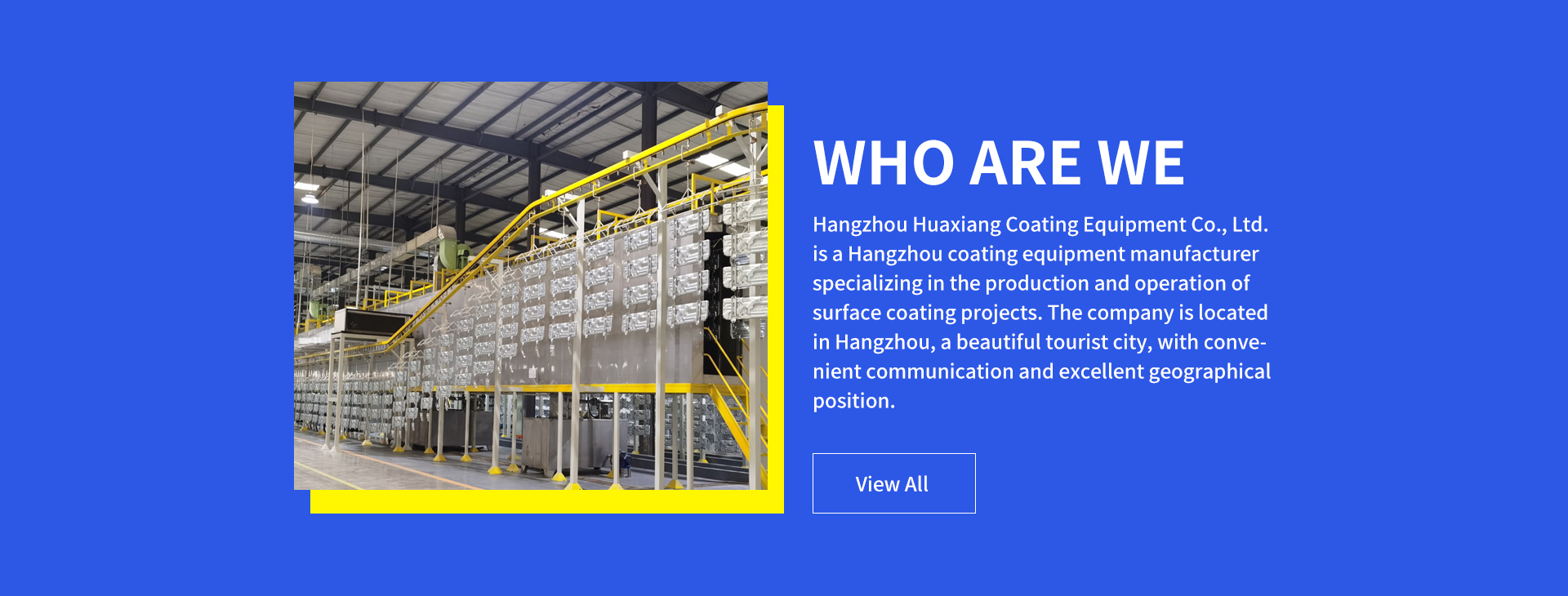

Disclaimer: Enhance your coating process with advanced electrostatic powder coating machines, precision powder coating spray guns, comprehensive powder coating systems, and efficient powder coating lines from Hangzhou Huaxiang Coating Equipment Co., Ltd. Designed for reliability and high-quality finishes, our solutions meet all your industrial powder coating machine needs. Contact us at sale3@cncolourspray.com